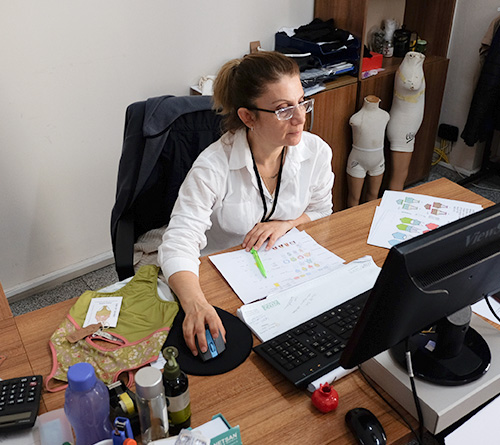

Behind Ozmoz’s success stands a passionate team whose creativity, experience, and innovation bring every design to life with care and vision.

From the designers who bring our collections to life, to the workshop team who carefully craft every detail in production; from fabric development to planning, from marketing to customer service—our entire staff represents the dedication and quality behind each of our products.

While closely following the latest trends in the fashion world, we always prioritize children’s comfort and parents’ expectations. Thanks to our team’s meticulous work at every stage—from sustainability to aesthetic details—Ozmoz products are not just garments, but meaningful pieces that carry value and are chosen with confidence.

We are a big family. And every member of this family is a vital part of what drives our brand forward.

Departments & Teams

Design Department

Our collections are shaped by our unique perspective, creative vision, and the dynamic needs of the industry. In this way, we offer solutions that help shape the future of fashion.

Sample Sewing Department

Each design begins with a meticulously crafted prototype sample, after which tailored size ranges are developed to form the basis of production.

Cutting Department

Every fabric designated for production is processed with next-generation automated cutting machines, making them ready for manufacturing. The integration of digitalized systems guarantees both efficiency and quality.

Finishing & Packing Department

Products that pass the quality control stage are sent to the final step—ironing and packing—where they are carefully prepared for sale.

Pattern Making Department

Every design is meticulously refined by our expert pattern team, where collection-specific size ranges ensure the perfect balance of aesthetics and functionality.

Sample Control

Each sample is meticulously inspected against various criteria. Every stage can be repeated until the perfect result is achieved.

Sewing Department

Every design is crafted by the sewing department through a lean production model, combining tailoring finesse with modern efficiency to deliver fast, precise, and flawless results.

Sample Cutting

The journey of our collections begins with prototype cutting; each piece is shaped with tailoring precision and the highest technical accuracy.

Fabric Quality Control

All fabrics designated for production are subjected to comprehensive quality control tests—including weaving inspections and shrinkage evaluations—and any fabric that fails to meet the standards is eliminated from the process.

Quality Control Department

Every product coming out of production is carefully inspected one by one. This control system, based on various criteria, ensures that the final product is flawless.